Here's how I route out "f" holes using an acrylic template.

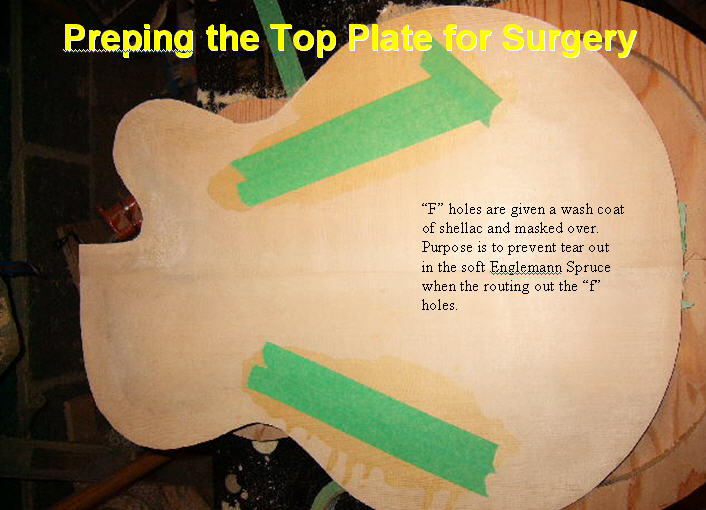

Once the plate is carved to the rough convex and concave desired thickness I trace on the "f" hole onto the convex side of the plate. I then give that part of the plate a wash coat of shellac in order to stiffen the fibres. Once dry I put masking tape on as extra insurance against blow out from the router bit.

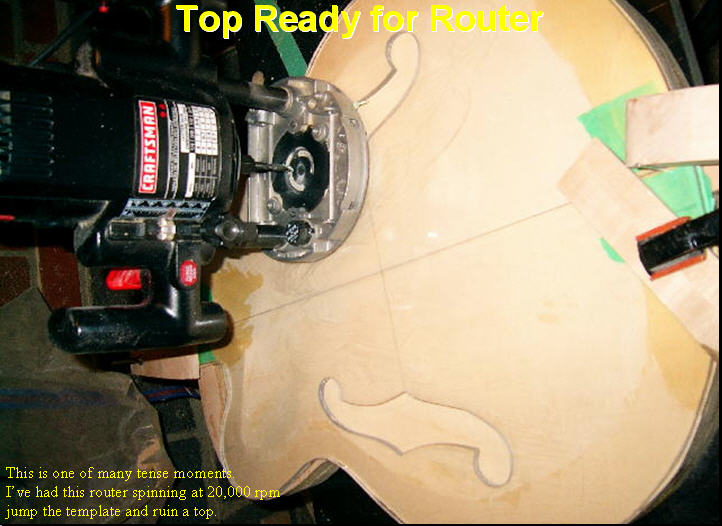

Next I attach my acrylic template to the concave side of the top plate. I put some masking tape on to the convex side of the plate then use doublesided carpet tape to attach the plate to the template. Note the template also has small brad nails through the centre line of the template that are lined up with the centre line of the tape. Next I clamp the template/top plate onto my carving dish as shown below.

I use a 3/8" template following guide in my router with a 1/4" upcut spiral router bit. If you use this method you will have oversize your template to compensate for the template following guide.

I cut out the f hole in one pass and have yet to experience blow out - though on a practice piece I did have the router jump once. The cause was not clamping the template down well.

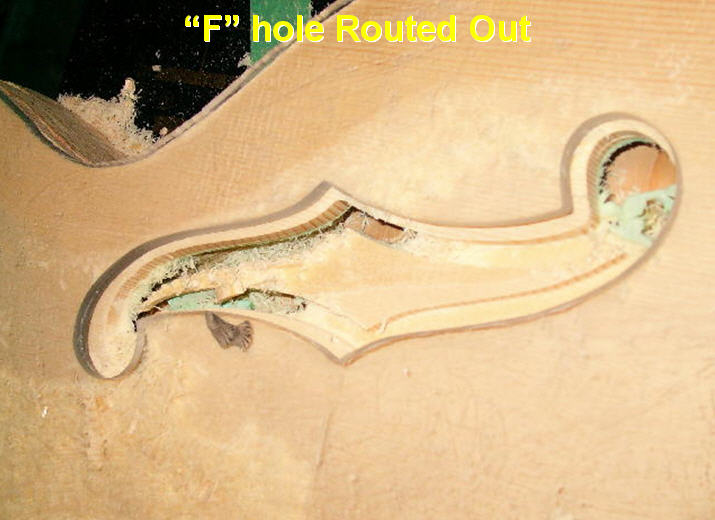

Here's the final product....voila

Thing about this method is that it works great with the tools most folks have on hand.

Thing about this method is that it works great with the tools most folks have on hand.